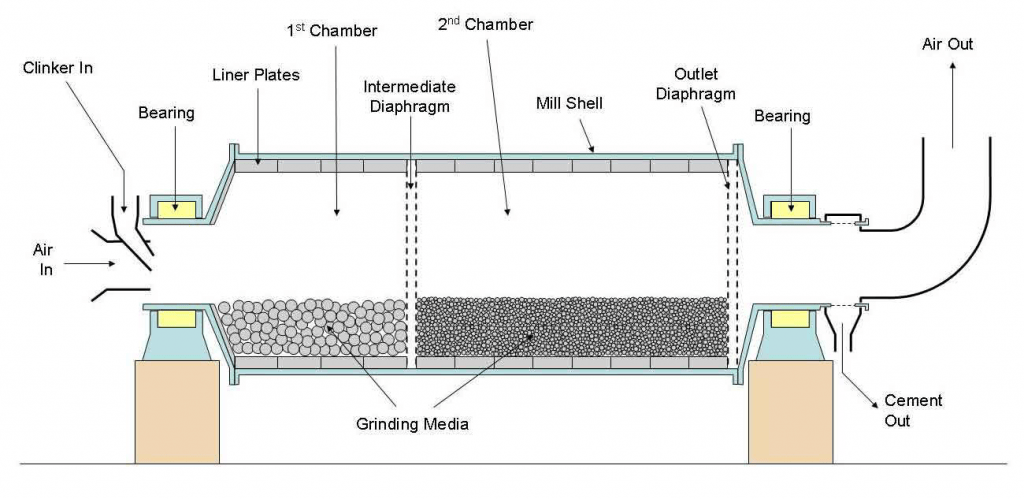

The ball mill is a piece of grinding equipment which grinds materials into fine powder in a very efficient manner. Today, the ball mill is considered as the most important piece of grinding equipment for crushing materials, as it can be used for grinding a variety of materials, such as cement, pyrotechnics, silicates, glass ceramics, fertilizer and many other hard materials.

- Ball Mill Working Principles

- Advantages of Ball Mill

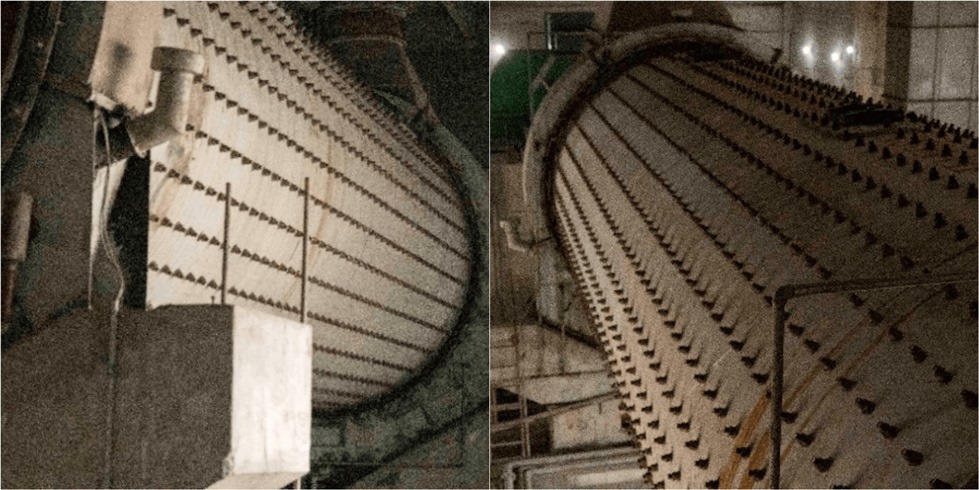

Ball mills have a number of advantages for milling solids either wet or dry. In order to minimize product contamination, ball mills can be constructed with a wide range of materials including abrasion-resistant high-chrome steel, alumina brick, and cast polyurethane.

Because all of the solids in a ball mill are forced to endure thousands of impacts by the grinding media over several hours, final particle size of 1-5 microns can be achieved and with narrow size distribution. Because ball mills are closed systems there is no chance for the finely divided solids to escape. Several of the independent variables can be reliably controlled including mill cylinder speed, media size, and of course time.

Many products cannot experience elevated temperature when milling and ball mills can accommodate this by jacketing the cylinder and circulating cold water. Ball mills are available from 0.1 to 5000 gal wet or dry capacity. The ball mill is extremely efficient for secondary grinding after crushing. The ball mill can grind all kinds of ores and other hard materials. Additionally, both primary and secondary grinding with a ball mill can be applied in a variety of industries.

Despite the effective and powerful grinding, the ball mill is a reliable and easy tool for operation. The ball mill has a very simple construction, yet simple working principle which certainly guarantees easy operation.